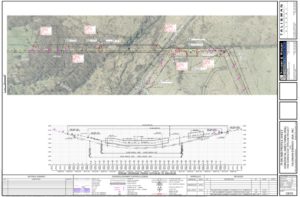

N&W served as the design consultant for t 78,500 linear feet of 16-inch low pressure and 20-inch high pressure natural gas gathering lines and associated spur lines in Bradford County, PA for Talisman Energy USA. N&W was responsible for the effective implementation of the project from conception, routing, field investigations, and design through to permitting and construction. In total, this project included tie-ins to 16 separate well pads. Project included a dual 16-inch and 20-inch trunk line and associated 12-inch, 10-inch, and 8-inch well spur lines. This project required boundary and topographic survey, wetland delineations, cultural resources, expedited ESCGP-1 permit approvals, Chapter 105 permit approvals for forty-eight (48) stream and wetland crossings , eight (8) PA DOT highway occupancy permits (HOP) and construction stakeout. This project was completed by avoiding all surface impacts to Waters of the United States, drastically reducing permitting times. To facilitate the no surface water impact approach this project included seven borings and sixteen horizontal directional drilled (HDD) crossings. HDD’s were implemented to cross under wetlands, streams and state routes. N&W facilitated the efficient design of these HDD crossings by conducting a field-based constructability assessment of rig-side workspace, pullback area, worksite access and safety concerns. Additionally, N&W applied industry standards to develop the conceptual design of these crossings developing reroutes as necessary to reduce the total length of these HDD crossings whenever possible. N&W also undertook a detailed geotechnical investigation in the areas of the HDD’s to identify the target materials formations and make recommendations about the maximum allowable mud pressure. As a part of regulatory requirements, N&W developed a detailed inadvertent return contingency plan. One of these HDD’s, the Wappasening Creek HDD (pictured below) was particularly technically challenging, due to its overall length, utility constraints, and proximity to a riser configuration. N&W assisted the HDD contractor during construction by completing a detailed construction stakeout of the centerline of the HDD and coordinated with the navigator to establish the design path and corresponding HDD boring machine setup. N&W reviewed the pilot hole punch-out location and made recommendations for the field revisions to incorporate the connection of the as-built HDD to the existing trenched pipeline. N&W further assisted the contractor with the implementation of the inadvertent return contingency plan however, no spill response was required during drilling.